We bridge the gap

Join Everypart for

Design

We help international companies and manufacturers in China and Southeast Asia work together more easily by combining engineering services, reliable production, and on-the-ground support.

- Engineering and manufacturing support across Asia

- Partner network of proven manufacturers in China and Southeast Asia

- Services for product design, sourcing, and production management

About Us

Our vision

Everypart is a young, growing team backed by industry experts with over 25 years of experience in business, service, and manufacturing. Our vision is to make cooperation between international companies and manufacturers in China and Southeast Asia transparent, predictable, and efficient — by closing the cultural, organizational, and operational gaps that exist between buyers and suppliers.

Mission

Our mission is to let both sides focus on their core strengths while Everypart handles sourcing, coordination, and day‑to‑day operations. We translate client needs into clear, actionable tasks and align expectations early — reducing risks and speeding up results.

Our experience

Our team brings practical experience in manufacturing, service, and cross‑border projects across China and Southeast Asia, supported by a network of reliable factories and domain experts. This combination of engineering competence and understanding of how decisions are made allows us to move quickly without compromising on quality.

Why Everypart

- Focused exclusively on connecting international buyers with trusted manufacturers in China and Southeast Asia.

- Engineering, manufacturing, and sourcing expertise combined in one team.

- Long‑term partnership mindset — we build relationships, not one‑off deals.

- Clear communication in English and Chinese at every stage, with additional language support available.

What We Do

Custom manufacturing services for industrial and mechanical products

Companies post orders. Qualified suppliers review specs, propose terms, and compete. The buyer picks the best match — Everypart connects, not decides.

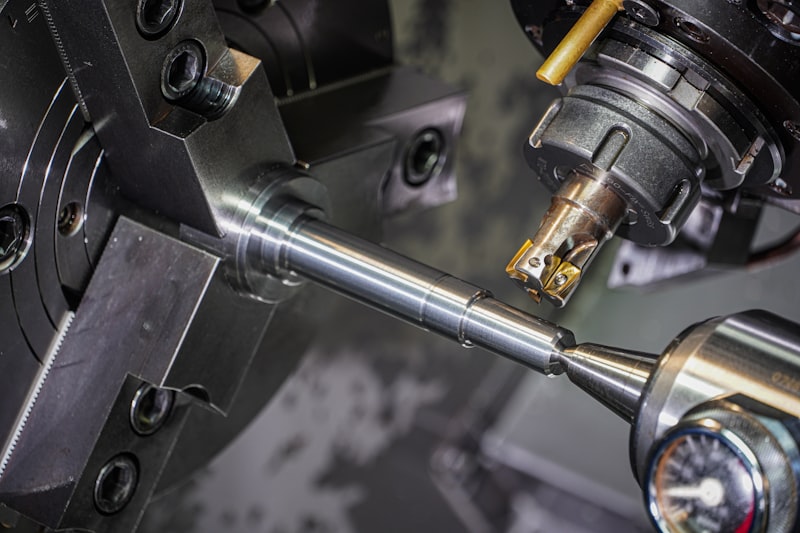

CNC Machining

CNC milling, turning, and drilling of metal and plastic parts — from prototypes to production batches with tight tolerances.

Sheet Metal

Laser cutting, plasma cutting, waterjet cutting, bending, and welding of sheet metal parts, enclosures, and assemblies.

3D Printing

Industrial additive manufacturing: FDM, SLA, SLS, MJF, and metal DMLS — for prototypes, functional testing, and small series.

Injection Molding

Plastic injection molding with custom tooling design and fabrication — from first samples through high‑volume serial production.

Vacuum Casting

Silicone mold casting for small series of plastic parts — ideal for pre‑production validation and bridge manufacturing.

Die Casting

Metal die casting for complex geometries with high dimensional accuracy — suited for medium and large production volumes.

Surface Finishing

Anodizing, powder coating, painting, electroplating, polishing, sandblasting, and other finishing processes for production‑ready parts.

Quality & Certification

Dimensional inspection, material certificates, test reports, and compliance documentation so every part meets your requirements.

Digital Services

Engineering that prepares products for manufacturing

Before a part reaches the factory floor it needs solid engineering behind it. Our digital services cover product design, documentation, electronics, and simulation — so your project arrives at production with fewer unknowns and shorter lead times.

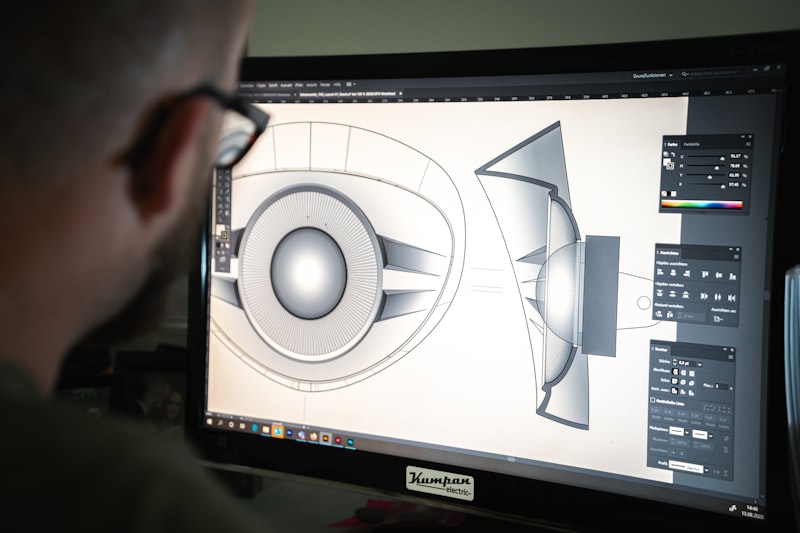

Industrial Design

Concept and industrial design for mechanical and electronic products — covering appearance, ergonomics, user scenarios, and design for manufacturability.

Technical Documentation

Preparation and refinement of drawings and technical documentation, aligned with real factory capabilities and applicable standards.

Electronics & Hardware Engineering

Circuit design, PCB layout, and integration with mechanical assemblies — delivered production‑ready so designs transfer smoothly to the factory.

Engineering Calculations & Simulation

Strength and thermal simulations combined with basic engineering analysis to validate and optimize designs before tooling and mass production.

Business Partners

We are looking for manufacturing partners in China and Southeast Asia

Join our supplier network and gain access to a steady flow of international projects. We work with manufacturing companies and engineering teams in China and Southeast Asia who are ready for long-term cooperation.

Manufacturing

CNC Machining & Metal Parts

High‑precision CNC machining and turning of metal components for industrial and mechanical applications.

Sheet Metal Fabrication

Laser cutting, bending, welding, and assembly of sheet metal enclosures, brackets, and frames.

Injection Molding & Tooling

Design and production of plastic injection molds and molded parts for serial manufacturing.

Electronics & PCB Assembly

Production of electronic modules, PCBs, cable harnesses, and electro‑mechanical assemblies.

Digital Product Services

Industrial Design & UX

Concept and industrial design for mechanical and electronic products, focusing on appearance, ergonomics, and manufacturability.

Mechanical & CAD Engineering

3D modeling of enclosures and assemblies, plus technical documentation aligned with real manufacturing constraints.

Electronics & Embedded Development

Circuit design, PCB layout, and basic embedded development for devices ready for serial production.

Engineering Analysis & Simulation

Strength and thermal simulations to validate and optimize designs before tooling and mass production.

Partnership Levels

Quality Confirmed

Prove your quality through a verification process matched to your supplier type — test order, portfolio review, or work-sample evaluation. Once confirmed, start receiving real orders.

Learn more →Verified Partner

Pass an on‑site audit or facility inspection and unlock priority access to large‑scale projects and long‑term contracts.

Learn more →Certified Partner

Become Everypart's regional representative — manage orders, inspect quality, coordinate logistics, and handle business operations on the ground.

Learn more →Agent

Represent Everypart in your region — connect local manufacturers with international buyers, manage client relationships, and grow the network on the ground.

Learn more →

Work Process

Easy steps to start cooperation

Our team is available for a conversation at any time. You can reach us by email, contact form, or book an online meeting — whichever is most convenient. Every request is reviewed and answered personally.

Learn about your company

We start by understanding what your company does, your main products or services, and who is involved in project decisions. This gives us the context we need to be useful from the first conversation.

Clarify goals and challenges

We discuss what you want to achieve, the problems you are facing today, and which results matter most in the near term. Together we define priorities and agree on what success looks like.

Agree on format and next steps

We propose a way to work together and define the first concrete step — with clear responsibilities and timelines on both sides. You finish the first call with an agreed action plan, not an open question.

Ready to get started?

Let's discuss how Everypart can help you achieve your goals. Reach out today for a free consultation.